UVC Ceramic pcb™

Advantages

Innovative Process

-

Increases the lifespan of the UVC LED

-

Reduces mercury content

-

Drives higher lumen for better sterilization

-

Utilizes lower cost pre-preg

-

Uses UV-resistant ceramic instead of epoxy

-

Uses patented Super Pillar™️ and 3-Pad Flip Chip™️ technology to dissipate the extreme heat

Patented Technology Combined

The innovative UVC Ceramic PCB™️ uses patented technology like the Super Pillar and the 3-Pad Flip Chip.

Combining our Super Pillar™️ technology with the 3-Pad Flip Chip™️ from our sister company, Flip Chip Opto, we're able to increase output, longevity, and lower thermal management costs. The UVC Ceramic PCB™️ is compatible with all 3-pads for full customizability.

High Power + Low Thermal Resistance

-

Patented 3-Pad Flip Chip Technology

-

1200W ~ 300W LED Module

-

Lower thermal management cost

-

Lowest Tj = Longer Life Span

-

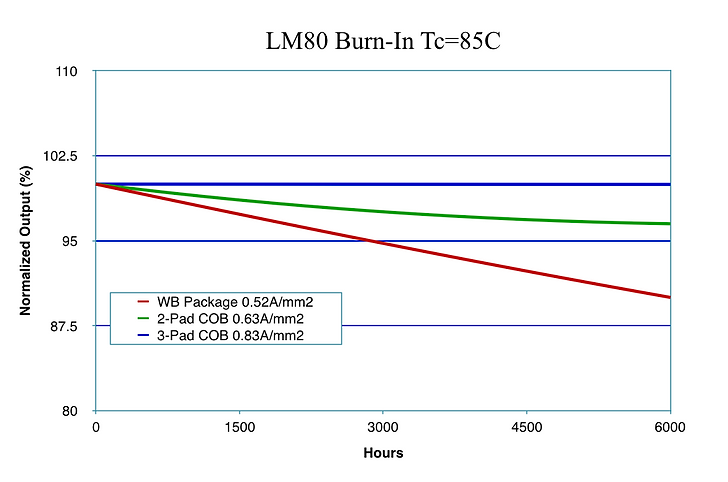

Minimal Thermal Decay

-

Flip Chip Opto is perfect for UVC (High T/O ratio)

Output and Longevity

Output and Longevity

Output and Longevity

UVC Wavelengths and Optical Power

Structure

-

MCPCB / Ceramic base

-

Cluster / Light bar / Panel

Wavelength

-

265nm / 280nm / 315nm

-

Mixture of Multiple Wavelengths

Optical Power

- 20mW ~ 100mW

-

100mW ~ 500mW

-

500mW ~ 1500mW

Conclusion

The UVC Ceramic PCB™ delivers a higher light output along with longer product life, better reliability, and an increase in cost-efficiency.

With the UVC Ceramic PCB™, COFAN can help you realize all the possibilities that UV LED technology provides, from self-sterilizing toothbrushes and cellphones to tunable sources for complex industrial applications—the possibilities are endless!

UVC Ceramic PCB™ Technology

UVC light is rapidly becoming a popular choice for air, water, and surface sterilization due to its inherent ability to render pathogens harmless without the use of harmful chemicals. UVC LED technology is revolutionizing the industry by providing a clean alternative to the standard, but toxic, mercury vapor lamps.

Whether it is water disinfection in residential applications, public water systems, swimming pools; surface sterilization in hospitals, packaging facilities; or air disinfection in buildings, UVC LEDs emerge as a winner due to their versatility, small form factor, and their low power consumption.

While UVC LEDs have clear advantages, the heat generated and the radiation produced prevents it from being a cost-effective solution. Conventional MCPCBs utilize an organic dielectric layer which slowly degrades due to UVC exposure, limiting its longevity.

COFAN's innovative UVC Ceramic PCB™ design addresses both problems by utilizing our newly patented Super Pillar™ technology combined with a ceramic substrate. The Super Pillar™ technology delivers exceptional thermal conductivity—up to 390W/mK, which is more than 100 times the heat dissipation of a conventional MCPCB. The Super Pillar™ achieves this impressive feat by bypassing the dielectric pre-preg and adding a direct thermal path to the copper base. Additionally, ceramic substrates provide excellent thermal dissipation and resistance to UV radiation.

Feature | Mercury Lamp | UVC LED | Benefits |

|---|---|---|---|

Life Span | <1.5 yrs | 3~5 yrs | Saving in cost |

Mercury Content | 20~200mg | 0 | Disposal / EU (2011) |

Warm Up | < 15 mins | < ns | Min. Waiting Time |

Surface T(°C) | 600°C | < 140°C | Surface Contamination |

Wavelength | 200~300nm | 265nm / 280nm | Energy Saving |

Structure | Cylindrical Tube | Package / COB | Flexibility (Fixture) |

Vf / I | 110/220 AC 0.5A~2A | 5.8~6.5V DC 20mA ~ 500mA | Battery / Solar Feasible |

UVC Comparison Table

APPLICATIONS

APPLICATIONS

UVC LEDs are mainly used for sterilization purposes. From simple applications like surface sterilization and food preservation to life-saving ones like hospital and surgical sterilization, applications for UVC LEDs are limited only by cost-effectiveness.

Innovative Processes

Water sterilization

Innovative Processes

Hospital sterilization

Innovative Processes

Food preservation

Innovative Processes

Surface sterilization

Innovative Processes

Air sterilization

Innovative Processes